Plan: Food Processing Facilities

Set the Path for Growing Your Food Operation.

Need to explore the feasibility of your ideas for a process expansion, building addition, or facility relocation?

Planning is the first step to address your questions, avoid costly mistakes, and turn your vision into a feasible business strategy. Our planning services help you evaluate options for growth and the corresponding investment implications that an expansion, renovation, or new construction project require.

Process Planning

Process planning develops your requirements for storage and production based on food processing capacity needs. Considerations for process flow, process equipment, technology, storage, and food safety are used to generate a process definition and space requirements for a new or expanded operation.

Facility Planning

Facility planning is an iterative process where various concepts for the floor plan are developed for your expansion, renovation, or relocation project. These floor plans are created using production flow and layout requirements developed during Process Planning.

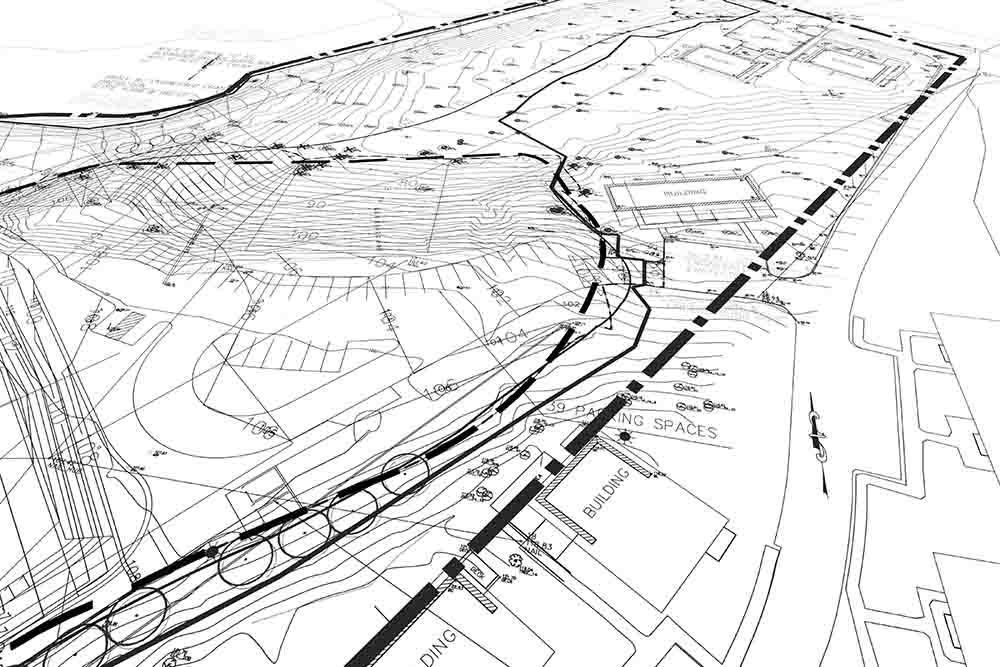

Site Planning

Site planning establishes the space available on a property for an addition or new building based on factors such as planning, zoning, and building code requirements. The site planning process also considers needs for parking, truck and car access, and availability of utilities such as water, sewer, and gas when locations on a site are being developed.

Master Planning

Master Planning is the augmentation of information developed during the Facility and Process Planning phases. Starting with the refinement of the process plan and facility plan, it also may include development of preliminary site plan information. Major building utility systems—such as HVAC, refrigeration, and electrical—are also quantified in order to develop building and process utility requirements.